Hill Machine Works, LLC

FIRST, FOCUSED & FAST

An operation where what is supposed to happen does happen, ontime, every time, day or night.

WHO WE ARE. WHAT WE DO.

At Hill Machine Works we provide an abundance of services. What they all have in common is we garuntee customer satisfaction with every job we take on. Below are just some highlights of what we can offer; head over to Services to see the full list.

LATEST NEWS

See what has been happening recently at Hill Machine Works

Now Hiring!

We are hiring light assembly first shift full time 7 am - 3:30 pm and part time second shift 3:30 pm - 7:00 pm. - Great for after school and re-entry into workforce!

Hill Machine Works is expanding our machine build division and we are looking for electrical enclosure / panel builders and PLC Programmers

Part time - Full Time available

Contact - Walter.hill@hillstdworks.com or Walter at 810-656-9234

Champion of the week

Meet - Yurkelis

Trucking Services

Meet "Duke" - If you are in need of any delivery services we may be able to assist.

RECENT SOCIAL POSTINGS

See what we projects and exciting things we have been working on recently at Hill Machine Works

4-15-2024

Looking for a reliable partner to build a part gage in a timely manner? Trust Hill MACHINE Works to deliver high quality solutions. Call us today at 586-238-2897.

4-15-2024

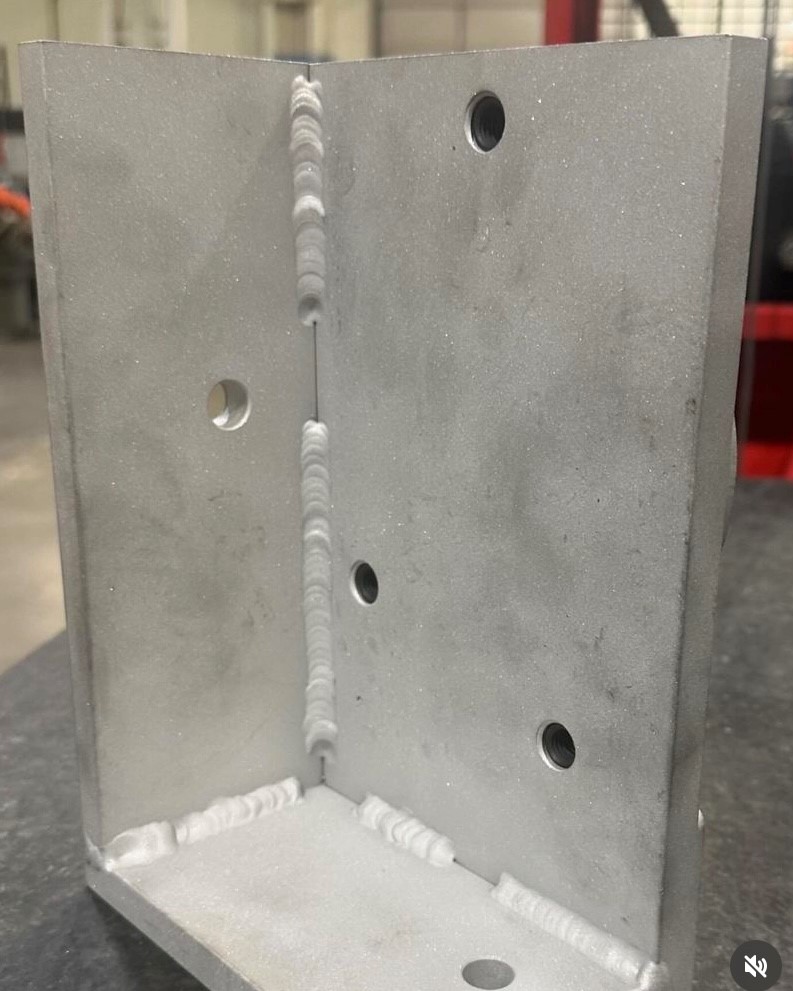

Experience the flexibility of choosing your preferred part washing trays fabrication method with Hill MACHINE Works. Whether it's 3D printing, stainless steel welding, or CNC Machining, we'll deliver high-quality solutions promptly. Contact us today at 586-238-2897 to discuss your needs.

4-4-2024

Get ready for a workout at our fab shop - we pump iron and make it look good! Need some fabrication or machine builds done? We got you covered. Give us a shout @ Hill MACHINE Works today.

586-238-2897

3-21-2024

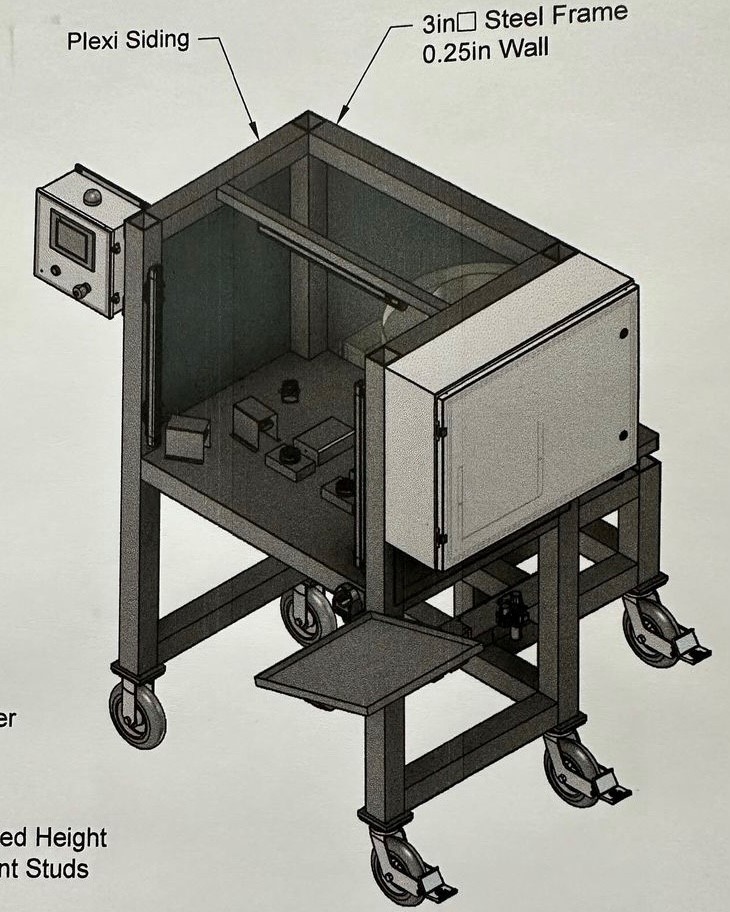

Hill MACHINE Works is currently working on another project in the queue, involving automated feeding of washers via a bowl feeder to our machine cylinder heads for accurate placement and staking over threaded inserts. The process will be monitored by multiple cameras to ensure proper alignment and no damage to the threads.

Call 586-238-2897

3-20-2024

Magnetic conveyor Stand shipping this morning.

This quick turn around fabrication of the stand and complete rebuild of the mag conveyor will assist the client in ensuring a quality product is efficiently getting to the finished goods bin

Call Hill MACHINE Works

586-238-2897

3-16-2024

Homestretch for this project.

This station has a megnetic conveyor table top mounted (We rebuilt the mag conveyor, tear down to individual components), reconditioned and reassembled, on the same end will be a shrouded add on to ensure NC parts cannot get mixed with finished goods. The station will also have easy access work instruction viability, cup holder, enhanced lighting and hardwood butcher block top.

Call Hill MACHINE Works

586-238-2897

2-29-2024

At Hill MACHINE Works, our team utilizes rapid prototyping to address customer issues promptly. This case our customer was using a vertical saw to cut logs into separate parts while exposing operator fingers to the blade. Which our client wanted resolved.

To ensure operator safety and protection from potential accidents, we have designed an in-house fixture that accurately holds each part during cutting without jeopardizing finger placement near the active saw blade.

After prove out, a production ready fixture will be mounted to all saws.

Call us, we can help

586-238-2897

2-24-2024

With the aim of streamlining production processes, Hill MACHINE Works has created an innovative fabrication solution that cuts down part processing times from 30 seconds to just 5 seconds using single personnel.

Give us a call

586-238-2897

2-24-2024

2-14-2024

Happy Valentines Day

Hill MACHINE Works showing a little love to associates - in addition to some heart shaped Krispy's a little Valentines bag filled with goodies and lotto tic'

It may be a Hallmark day but it's a good opportunity to express our gratitude to those that rise each morning and choose to spend their days with us.

One love ~!~

2-4-2024

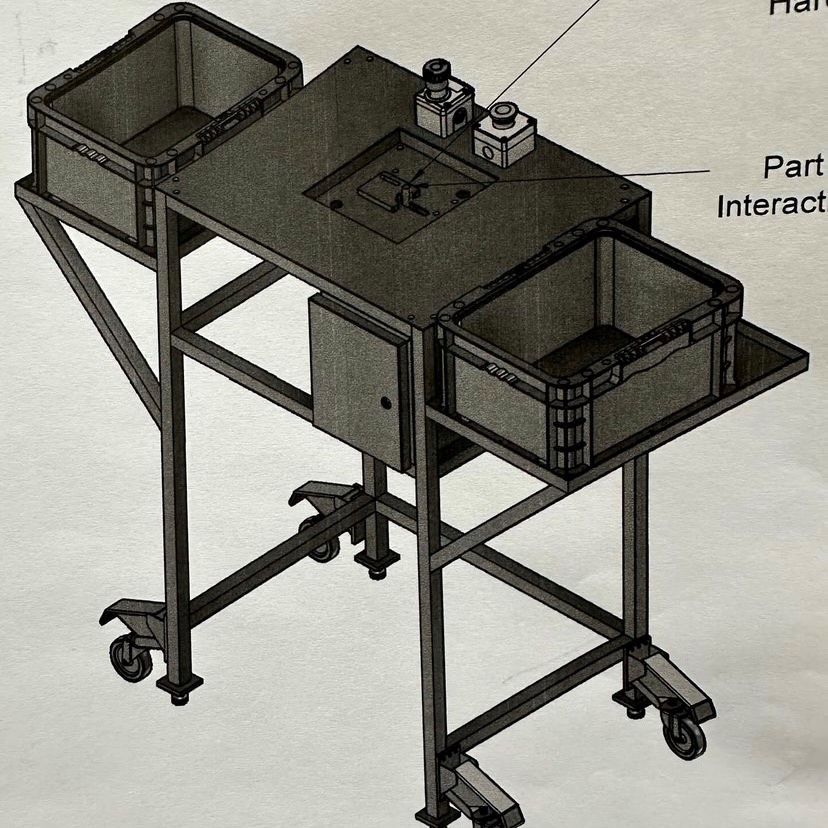

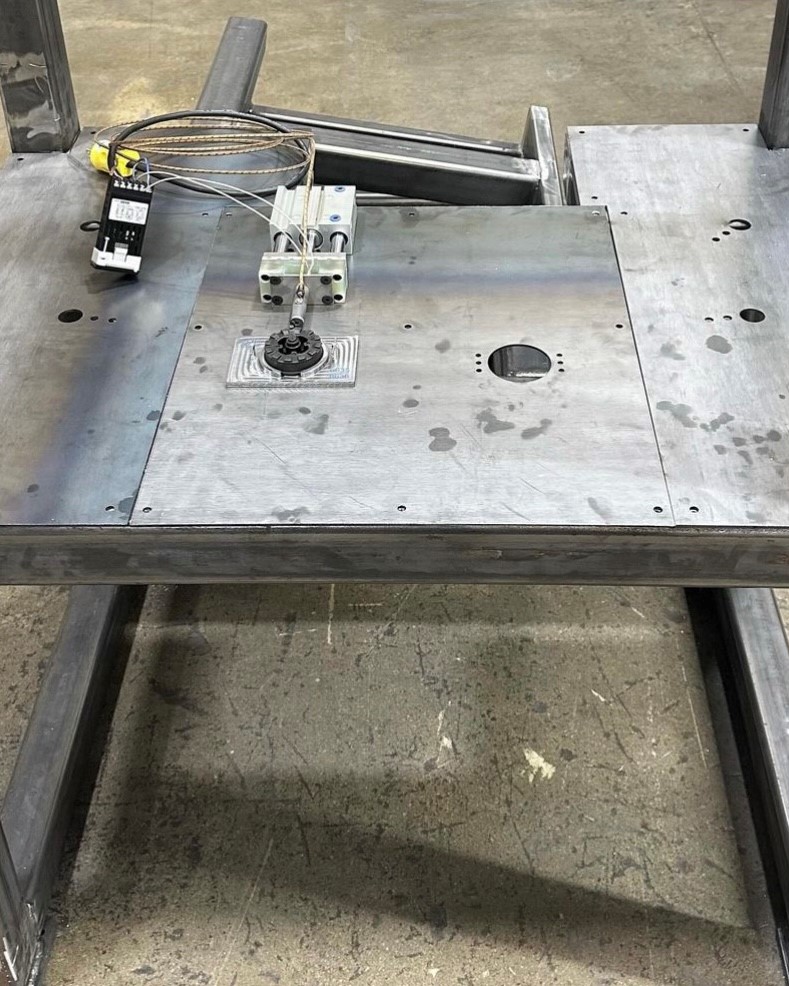

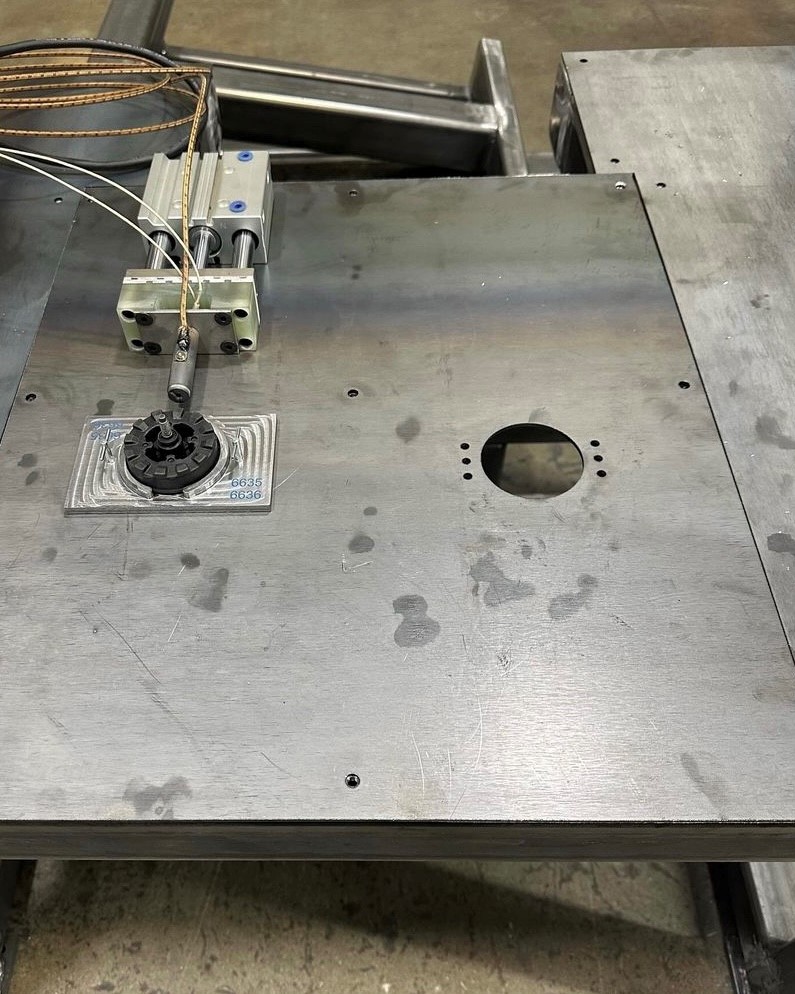

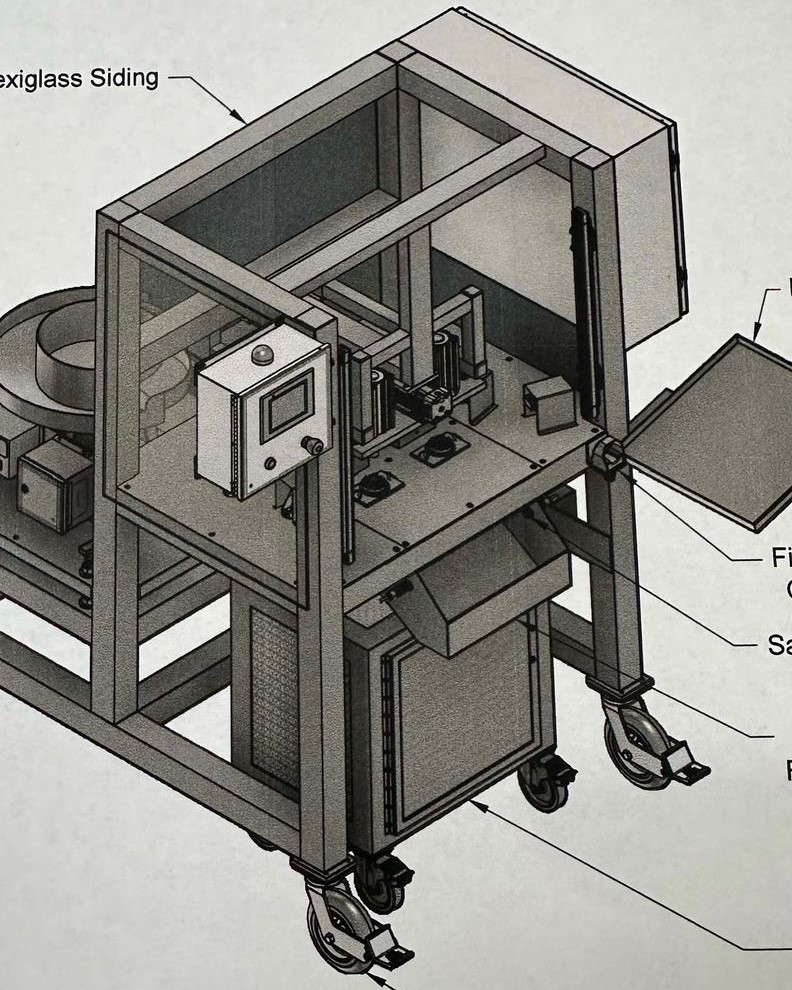

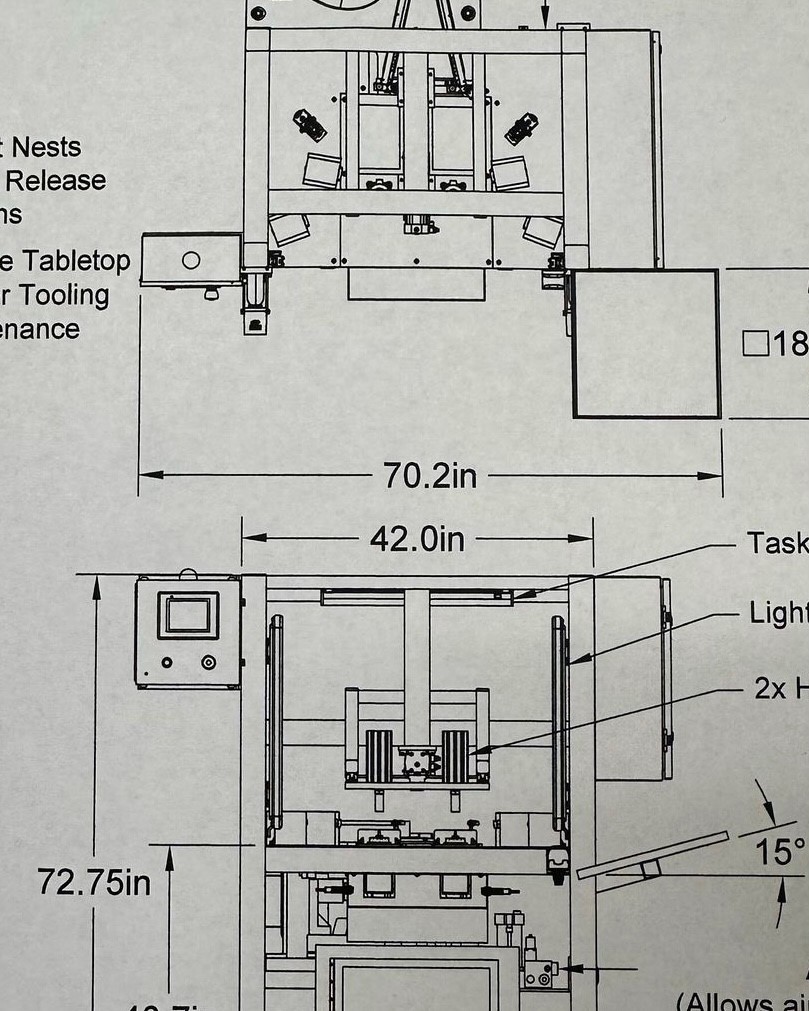

Hill MACHINE Works - our next machine build begins~another exciting time from design to the machine coming alive.

This machine will stake washers that will be bowl fed, and staked over a threaded bolt - 2 out auto dispense, good parts to the operator and any non-conforming dropped through inot a locked NC bin.

Error proofing via part sensors and cameras

Stay tuned

Call us - we are here to provide solutions - First, Focused and Fast

586-238-2897

Walter.hill@hillstdworks.com

Thread Rolling

Our Mig, Tig and resistance welding services can meet all your needs for carbon steel, stainless steel, aluminum, and specialty steels.

Assembly

Hill Machine Works machining operations focuses on error proof processing and lean manufacturing to machine and deliver the highest quality parts. We are proficient in tight tolerances and consistently producing a quality product. We work with a wide range of materials from steel, stainless steel, bronze, plastics, aluminum and beyond.

Repetitive Manufacturing

Specializing in manufacturing and assembly for the automotive and defense industries we can handle nearly any type of industrial or manufacturing assembly service including automotive, aerospace and more.

Quality is designed into production by observing the standards of the industry. This enables us to manage your needs and exceed your expectations.

Automation

Hill Machine Works provides fully and semi-automated assembly equipment. Our semi-automated assembly cells can handle multiple tasks to meet your specific manufacturing requirements, increase production, and reduce costs with shorter cycle times and improved operator ergonomics.

QUALITY POLICY

Hill Machine Works, LLC. is committed to the Quality of our products and services to meet customer expectations through continuous improvement to the Quality Management System.

NAICS 39999-541611

Cage Code: 70SZ4

DUNS#: 079181437